About Product

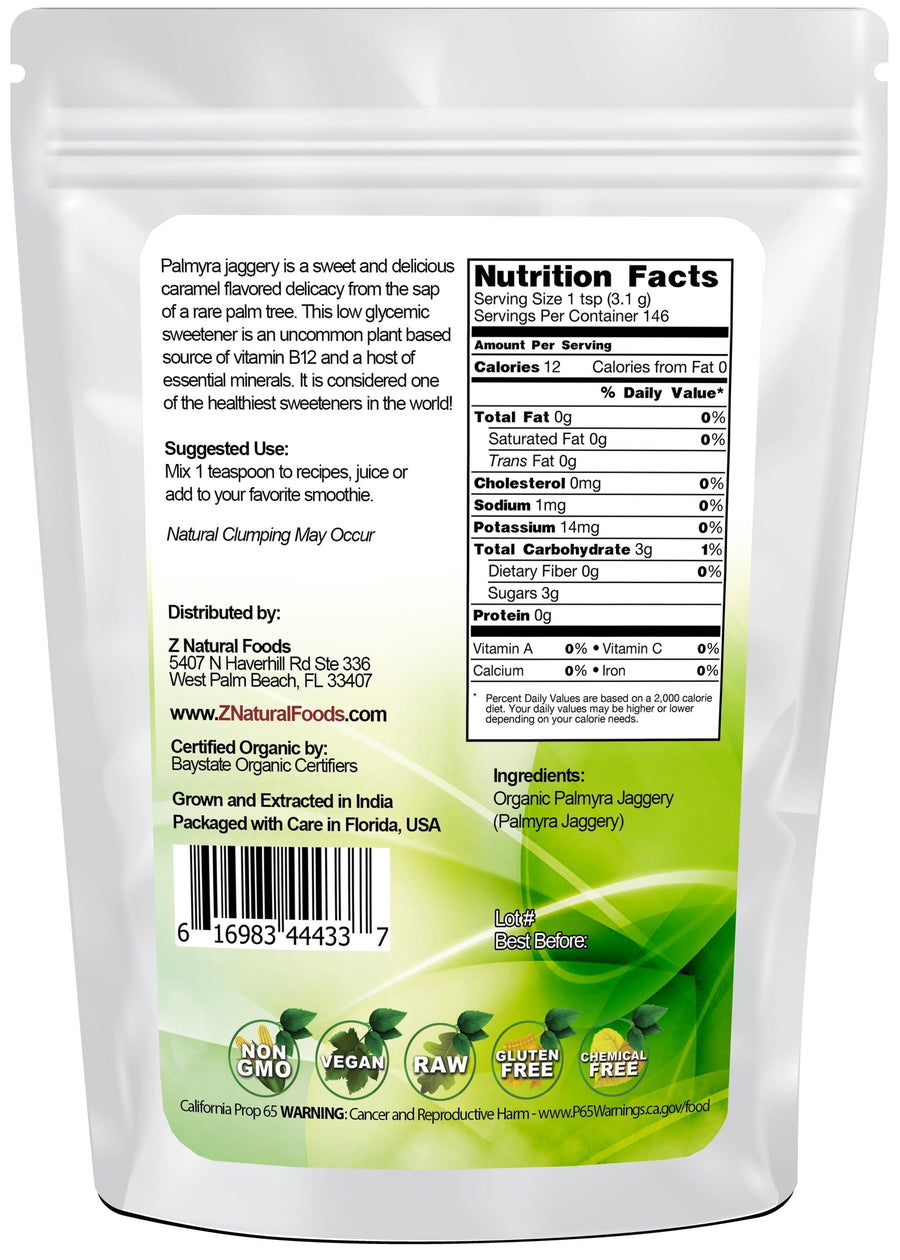

Organic Palmyra Jaggery is a traditional, unrefined sweetener made from the sap of the Palmyra palm tree. It is an ancient food used in India for centuries and is known for its unique flavor and health benefits.

Palmyra Jaggery contains numerous vitamins and minerals, including iron, calcium, and potassium.

In addition, Palmyra Jaggery is a natural energy source and is said to have several therapeutic properties. It can be used as a natural sweetener in tea, coffee, and other beverages, as well as in baking and cooking.

It can also be enjoyed as a snack or dessert. Organic Palmyra Jaggery is a healthy alternative to sugar.

Constituents of Palmyra Jaggery include:

- Calcium, Magnesium, Potassium, Phosphorus, Iron, Copper

This product is 100% natural and minimally processed. Taste, smell, texture, and color vary from batch to batch. Due to its nature, this powder tends to clump. If clumping occurs, lay the bag on a flat surface and place a towel over the bag. Then pound on the bag until the clumps break up. The towel will help protect the bag from damage.

Suggested Use: Mix one teaspoon of recipe juice, or add to your favorite smoothie.

Mixing Suggestions: To increase flavor and nutritional profile, combine with our organic ginger and cinnamon powders.

Botanical Name: Borassus flabellifer.

Other Names: Gula melaka, gula merah, karupatti, thati bellam, Pamlyra Palm Sugar, Palmyra Jaggery.

Parts Used: Palmyra Sap (only the nectar).

Ingredients: Palmyra Jaggery.

Origin: Grown and extracted in India and packaged with care in Florida, USA.

Certifications: Certified USDA Organic.

How to Maintain Optimum Freshness

- This product is packaged in airtight stand-up, resealable foil pouches for optimum freshness.

- Once opened, push the air out of the pouch before resealing it to preserve maximum potency.

- Keep your powder in a cool, dark, dry place.

This product is 100% natural and minimally processed:

Taste, smell, texture, and color vary from batch to batch. Go here to learn why our products may naturally vary.

The important protections we take to bring you safe and nutritious superfoods:

Please go here to discover the essential steps we take to deliver fresh, quality nutrition.

Bulk Quantities?

Need to order a large quantity of our products? We are happy to help! Please get in touch with our Bulk department to discuss the details.

* Product packaging, pictures, and origin may vary.

Sources & References

1. "New improvements in

2. Uppal, S. K., and Sharma, S. (2002). Effect of storage temperatures on jaggery (

3. "Jaggery and Confectionery". APEDA, Ministry of Commerce & Industry, Government of India. Retrieved 2009-06-19.

4. Kalra, J.I.S.; Das Gupta, P. (1986). Prashad Cooking with Indian Masters. Allied Publishers Private, Limited. p. 10. ISBN 9788170230069. Retrieved 2015-09-13.

5. "Brown Sugar from Okinawa | Art of Eating". artofeating.com. Retrieved 2015-09-13.

6. http://www.organicfacts.net/nutrition-facts/others/what-is-jaggery.html

7. http://easyayurveda.com/2013/02/20/jaggery-health-benefits-and-usage-ayurveda-details/

8.

9. http://www.financeindia.org/Abstracts.htm, accessed December 18, 2007.

10. http://www.sundaytimes.lk/060903/ft/2.1.html, accessed December 18, 2007.

11. Uppal, S.K.

12. Adams O, Kaufman S,

13. World Health Organization, International Society for Burn Injuries. Injuries & violence prevention—facts about injuries. Burns, August 2004.

14. American Burn Association Prevention Committee. Scalds: A Burning Issue—A Campaign Kit for Burn Awareness Week 2000.

15. Agarwal, M. L., Dua, S. P.

16. Baboo, B.

17. Baboo, B. (1993).

18. Baboo, B. (1999). Sugarcane processing for health-friendly sweetener -

19. Kapur, J.

20. Roy, S. C. (1951). Gur monograph. IIST, Kanpur: 285–288.

21. Uppal, S. K.

22. https://www.ayurtimes.com/jaggery-nutritional-value-nutrition-facts-analysis/

23. Personal Communication, Christian Medical Center Vellore, Pediatric Nursing, 2006.

23. "Media | Practical Action" (PDF). Itdg.org. Retrieved 2011-09-28.

24. https://www.getthegloss.com/article/healthy-but-tasty-sugar-alternatives-explained

25. Thakur, A.K. In Potential of jaggery (Gur) manufacturing in Punjab state, Proceedings of the national seminar on status, problems, and prospects of jaggery and

26. Pattnayak, P.K.; Misra, M.K. Energetic and economics of traditional

27. Dalibard, C. Overall view on the tradition of tapping palm trees and prospects for animal production. Livestock Research for Rural Development 1999, 11(1), 1–37.

28. Singh, J. In Research contributions of All India Coordinated Research Project on processing, handling

29. Sahu, A.P.; Paul, B.N. The role of dietary whole sugar- jaggery in

30. Rice, P.; Selman, J.D.; Abdul-Rezzak, R.K. Effect of temperature on thermal properties of ‘Record’ potatoes. International Journal Food Science and Technology 1988, 23, 281–286.

31. Unklesbay, N.; Unklesbay, K.; Hsieh, F.;

32. Nesvadba, P.; Eunson, C. Moisture and temperature dependence of thermal diffusivity of cod minces. Journal of Food Technology 1984, 19, 585–592.

33. Taiwo, K.A.; Akanbi, C.T.; Ajibola, O.O. Thermal properties of ground and hydrated cowpea. Journal of Food Engineering 1996, 29, 249–256.

34.

35. Oliveira, G.S.; Trivelin, M.O.;

36. Singh, R.P. Heating and cooling processes for foods. In Handbook of Food Engineering; Heldman, D.R.; Lund, D.B.; Eds Marcel Dekker: New York, 1992; 247–276.

37. Sweat, V.E. Experimental values of thermal conductivity of selected fruits and vegetables. Journal of Food Science 1974, 39, 1080–1083.

38. Krokida, M.K.; Panagiotou, N.M.; Maroulis, Z.B.; Saravacos, G.D. Thermal conductivity: Literature data compilation for

39.

40. Maccarthy, D.A. Effect of temperature and bulk density on thermal conductivity of spray-dried whole milk powder. Journal of Food Engineering 1984, 4 (4), 249–263.

41. Kent, M.; Christiansen, K.; van Haneghem, I.A.; Holtz, E.; Morley, M.J.; Nesvadba, P.; Poulsen, K.P. Cost 90 collaborative measurements of thermal properties of foods. Journal of Food Engineering 1984, 3 (2), 117–150.

42. Singh, P.C.; Singh, R.K.; Bhamidipati, S.; Singh, S.N.; Barone, P.

43. Maroulis, Z.B.; Drouzas, A.E.; Saravacos, G.D. Modelling of thermal conductivity of granular starches. Journal of Food Engineering 1990, 11, 255–271.

44. Sabliov, C.M.; Heldman, D.R. A predictive model for thermal conductivity of an intermediate moisture granular food. Journal of Food Process Engineering 2002, 25 (2), 91–107.

45. Tenou, E.; Fitzpatrick, J.J.; Synnott, E.C. Characterisation of food powder flowability. Journal of Food Engineering 1999, 39, 31–37. 886 RAO, DAS, AND DAS

46. Vega, C.; Esther, K.; Xiao, D.C.; Roos, Y.H. Solid-state characterization of spray-dried ice cream mixes. Colloids and Surfaces B: Biointerfaces 2005, 45, 66–75.

47. Linden, G. Methods of particle size analysis. In Analytical Techniques for Foods and Agricultural Products; Melcion J.P.; Monredon, F.De.; Eds.; VCH Publishers: New York, 1996; 229–248.

48. Association of Official Analytical Chemists. Official methods of analysis. AOAC: Washington, DC, 1998.

49. Jagannadha Rao, P.V.K.; Das, S.K.; Das, M. Moisture sorption isotherms of sugarcane,

50. Sharma, D.K.; Thompson, T.L. Specific heat and thermal conductivity of sorghum. Transactions of the American Society of Agricultural Engineers 1973, 16 (1), 114–117.

51. Fontana, A.J.; Wacker, B.; Campbell, C.S.; Campbell, G.S. Simultaneous Thermal conductivity, Thermal resistivity, and Thermal diffusivity measurements of selected foods and soils. Paper presented, American Society of Agricultural and Biological Engineers Annual International Meeting (paper no. 016101), July 30–Aug. 1, 2001, Portland, OR.

52. Perez-Alegria, L.R.; Ciro, H.J.; Abud, L.C. Physical and thermal properties of parchment coffee bean. Transactions of the American Society of Agricultural Engineers 2001, 44 (6), 1721–1726.

53. Sweat, V.E. Thermal properties of foods. In Engineering Properties of Foods; Rao M.A.; Rizvi, S.S.H.; Eds.; Marcel Dekker: New York, 1986; 99–138.

54. Origin. Non-Linear Curve Fit., Ver.6.1 2000, Origin Lab: Northampton, MA, 2000.

55. Microsoft Office Professional Edition. Microsoft Office Excel 2003, Microsoft, Inc.: Redmond, WA, 2003.

56. Muramatsu, Y.; Tagawa, A.; Kasai, T. Effective thermal conductivity of rice flour and whole and skim milk powder. Journal of Food Science 2005, 70 (4), 279–287.

57. Singh, R.P.; Heldman, D.R. Thermal conductivity of selected food products.

58.

* Reviews & Success Stories Disclaimer

Product reviews solely reflect the views and opinions expressed by the contributors and not those of Z Natural Foods. Z Natural Foods does not verify or endorse any claims made in these reviews. Statements have not been evaluated by the FDA and are not intended to diagnose, treat, cure, or prevent any disease or health condition.REFERRAL PROGRAM

Share your personal link to your friends and welcome them with rewards. Claim yours when they make their first purchase.

GIVE

$10 off discount

GET

$10 off discount

Other products in the same category

Stevia Leaf Powder - Organic

$21.99

Erythritol

$6.99